HORAL boilers 25-30 kW power series are manufactured in hot-water with max. leaving water temperature 90 ° C. The used fuel is dry pieces of wood.

The design is adapted to the requirements of standard EN 303-5.

The design is adapted to the requirements of standard EN 303-5.

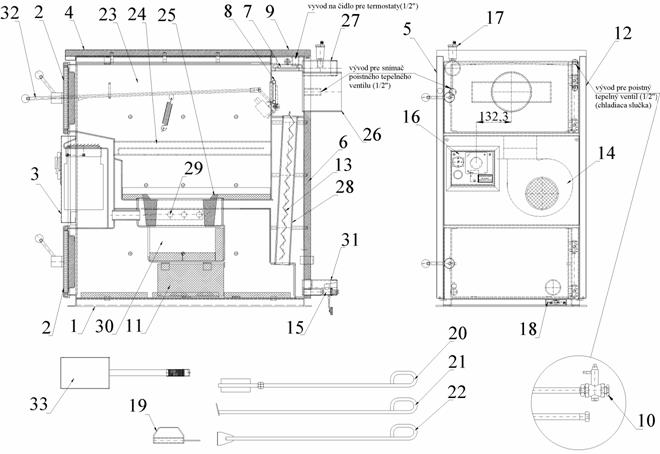

A description of the

1. Boiler body

2. Door H + D

3. Cover the fan

4. Close the top front

5. Cover the left side

6. Back cover

7. Cover the internal heat exchanger

8. The closing flap

9. Cover outdoor heat exchanger

10. The safety thermal valve (not part of the boiler)

11. Lining

12. Cover side right

13. Insert whirlpool

14. Fan

15. Drain cock 1/2 "

16. Electrical switchgear

17. Self-venting valve 3/8 "

18. Rating plate

19. Peeler tar

20. x

21. x - scraper

22. x - whisk pipe exchanger

23. Place the tray

24. The management of primary air

25. Nozzle (fireproof nozzle)

26. Chimney throat

27. Socket outlet water

28. Pipes exchanger

29. Secondary air

30. The combustion chamber

31. Throat return water

32. Lever closure flap

33. Scapula

All detailed technical data can be found in a section of documents.

Assembly of a boiler in the boiler is installed on the base, which lies in the user's connection to the system, the connection to the chimney. Installation of the boiler by the user consists in installing the boiler concerned, which is linked to the heating system, connection to the chimney. The boiler is connected to a network is to connect the power cord plug into the socket. The boiler is not supplied, but the system must be built pressure relief valves, thermometers, barometers and either thermal relief valve, or storage tanks.